Expert Research & Development Teams

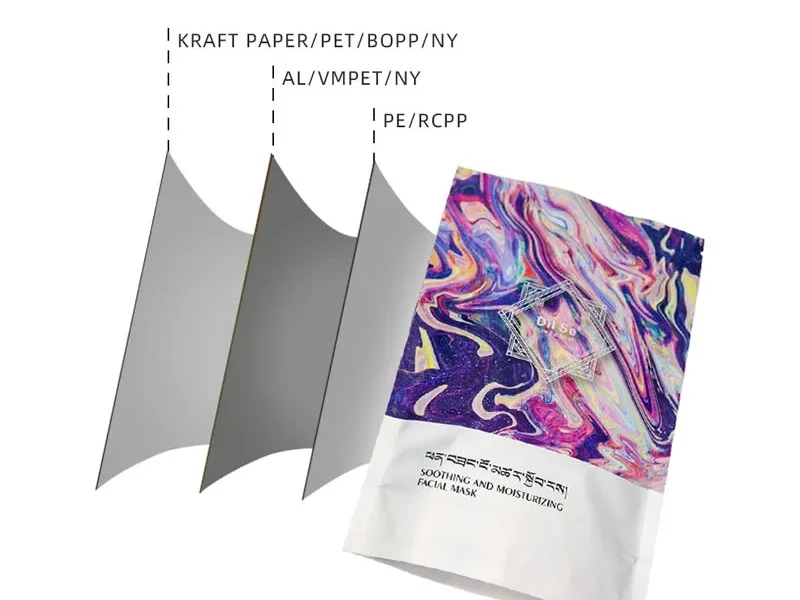

Food Pack Pouch has our R&D team, which focuses on researching and developing flexible packaging and materials, Product Specifications Management, and Regulatory Compliance Management…

With extensive experience in flexible packaging, Kinderway can continue pushing the envelope with new structures, new materials, recyclable packaging, improved sustainability, and more.

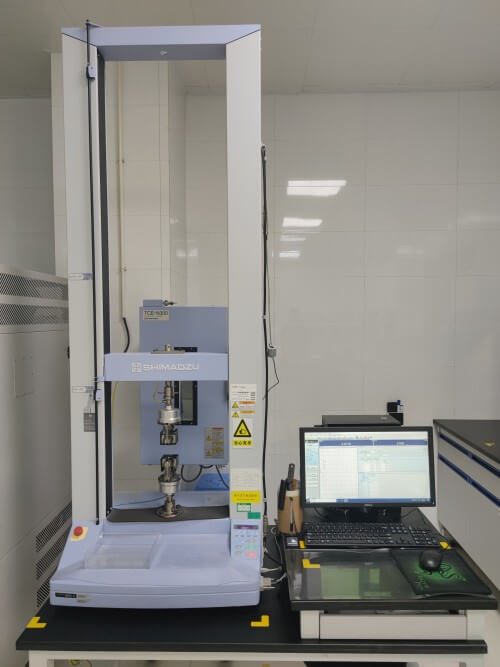

Electric Universal Tester

The electric universal tester assesses and measure various mechanical properties of the pouch material. This testing equipment applies controlled forces and measures the corresponding responses to evaluate the strength, flexibility, and overall performance characteristics of the plastic pouch.

Xenon Lamp Weather Resistance Tester

The xenon lamp weather resistance tester is to simulate and assess the effects of outdoor weather conditions, particularly sunlight exposure, on the durability and performance of the pouch material. By subjecting plastic pouch samples to controlled exposure to this simulated sunlight, the tester can evaluate the pouch’s resistance to UV degradation, color fading, material aging, and other weather-related factors.

Molud Incubator

The mould incubator is to study the susceptibility of plastic pouch materials to mold growth, assess the effectiveness of anti-microbial treatments or packaging solutions, and evaluate the overall mold resistance of plastic pouches. By simulating real-world conditions, mold incubators help in identifying potential mold-related issues, ensuring the quality and safety of plastic pouches, and developing strategies to prevent mold contamination during storage or transportation

Oxygen Permeation Analyzer

The Oxygen Permeation Analyzer is used to measure the oxygen permeability or transmission rate of the pouch material. It assesses how effectively the pouch can prevent the ingress or egress of oxygen, which is important for products that are sensitive to oxygen exposure.

Water Vapor Permeability Tester

The Water Vapor Permeability (WVP) Tester for plastic pouches is used to measure the water vapor permeability of the pouch material. It assesses the ability of the pouch to allow water vapor to pass through it, indicating its barrier properties against moisture

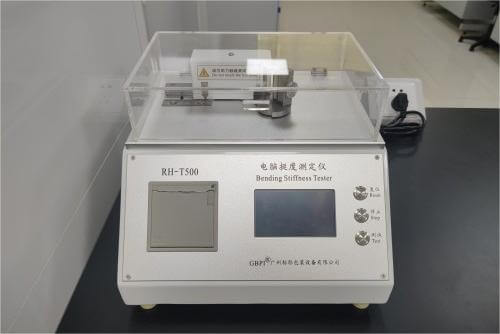

Bending Stiffness Tester

The Bending Stiffness Tester is to quantify the resistance of the plastic pouch material to bending or flexural deformation. This test helps evaluate the stiffness, flexibility, and overall mechanical properties of the pouch.

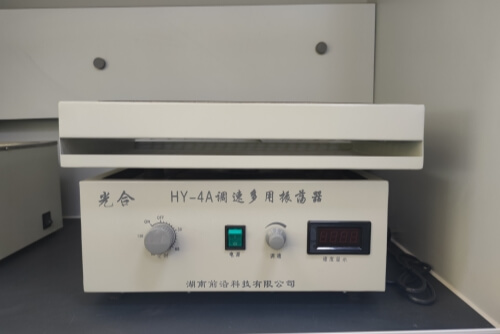

Variable-speed Multipurpose Oscillator

The variable-speed multipurpose oscillator is used in various pouch processing and manufacturing applications. It provides adjustable oscillation or vibration at different speeds, offering flexibility and versatility in handling different types of plastic pouches and processes.

Electro- thermal Incubator

The electro-thermal incubator is commonly used for tasks such as heat sealing, drying, curing, or testing the heat resistance of plastic pouches. It ensures consistent and uniform heating throughout the incubation chamber, allowing for reliable and efficient processing of the pouches.

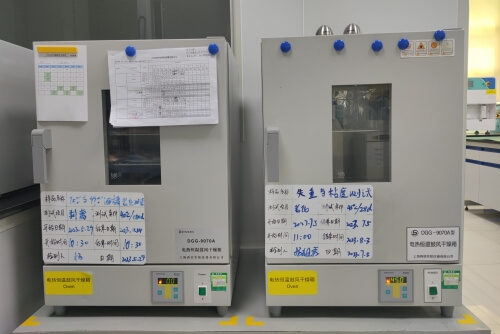

Electric thermostatic air drying oven

The mould incubator is to study the susceptibility of plastic pouch materials to mold growth, assess the effectiveness of anti-microbial treatments or packaging solutions, and evaluate the overall mold resistance of plastic pouches. By simulating real-world conditions, mold incubators help in identifying potential mold-related issues, ensuring the quality and safety of plastic pouches, and developing strategies to prevent mold contamination during storage or transportation