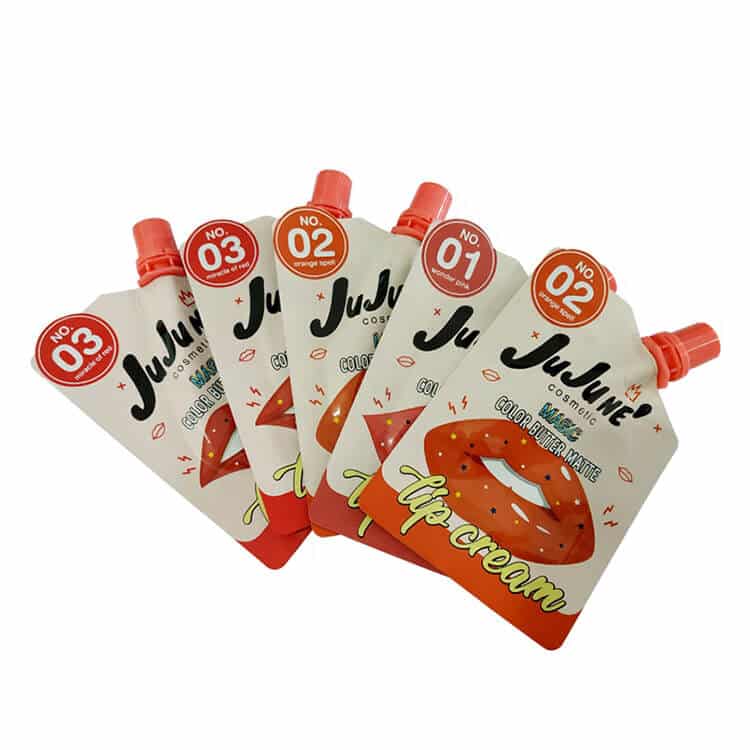

Lipstic Packaging Spout Pouch

A Lipstick Packaging Spout Pouch is an innovative, flexible packaging solution designed for liquid, gel, or cream-based lip products, such as liquid lipsticks, lip glosses, lip stains, or hybrid formulas. Unlike traditional rigid lipstick tubes, this format combines portability, precise dispensing, and modern aesthetics

Applications

- Liquid Lipsticks: Precision application for long-wear, matte, or glossy formulas.

- Lip Glosses: Hygienic dispensing without dipping fingers or applicators.

- Lip Balms/Oils: Portion-controlled delivery of nourishing oils or butters.

- Hybrid Products: Mixable dual-chamber pouches (e.g., pigment + gloss in one pouch).

- Travel/Disposable Kits: Single-use pouches for sampling or on-the-go touch-ups

Benefits

- Hygiene: Avoids contamination from repeated finger dipping (common in jars).

- Preservation: Airless dispensing minimizes exposure to oxygen, extending shelf life.

- Sustainability: Refillable or recyclable options reduce plastic waste vs. rigid tubes.

- Premium Appeal: Sleek, modern design stands out on shelves and aligns with clean beauty

Innovations & Trends

- Eco-Friendly Materials:

- Mono-material spout pouches (e.g., all-PP) for easier recycling.

- Bio-based films (e.g., sugarcane-derived PE) or compostable laminates.

- Smart Features:

- Built-in applicators (e.g., brush or rollerball tips integrated into the spout).

- QR codes linking to tutorials or shade-matching tools.

- Multi-Functional Design:

- Dual-spout pouches for two-step lip products (e.g., primer + color).

- Transparent windows to showcase product color/texture.

- Luxury Finishes:

- Foil stamping, embossing, or soft-touch coatings for a high-end feel.

Comparison to Traditional Lipstick Packaging

| Feature | Spout Pouch | Traditional Tube |

|---|---|---|

| Portability | Ultra-lightweight, flexible | Rigid, bulkier |

| Hygiene | Reduced contamination risk | Risk from repeated applicator contact |

| Sustainability | Recyclable/refillable options emerging | Often mixed materials (hard to recycle) |

| Dispensing Precision | Controlled, no product waste | Over-application common with doe-foots |

| Cost | Higher upfront, lower shipping costs | Lower upfront, higher shipping weight |