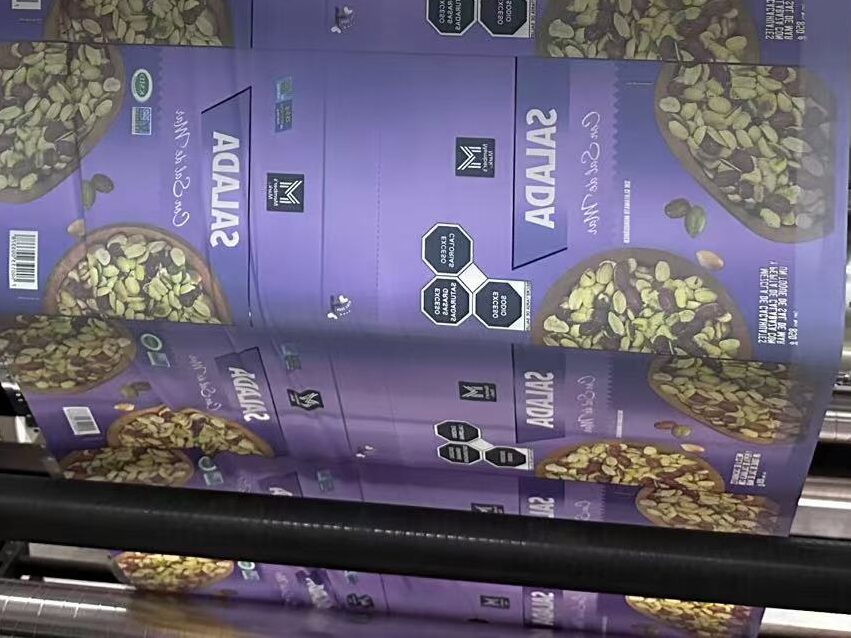

Gravure printing (also known as rotogravure printing or roto printing) is a widely used printing process for high-quality and high-volume packaging, including flexible plastic pouches. It is ideal for detailed, continuous patterns and vivid colors, making it popular for food packaging, liquid pouches, and other flexible materials.

Advantages of Gravure Printing

High-Quality Prints

Produces sharp, detailed designs with consistent color density and vibrancy

Durability

Gravure inks are long-lasting and resistant to abrasion, making them suitable for flexible packaging that undergoes handling and transportation.

Efficient for Large Runs

Cost-effective for high-volume production due to economies of scale

Wide Material Compatibility

Works on various substrates, including PET, BOPP, PE, and laminated films. Max 1.3m wide printing

Complex Designs Max 11C

Handles intricate patterns, gradients, and continuous tone images seamlessly. It could be printing max 11 colors

Cheap Cost

Gravure printing is more cost-effective than digital printing, cuz it is high-speed printing and lower-cost ink than digital

Suitable for High-Volume Production

Cost-Effective for Large Runs: While the setup costs are high, the per-unit cost decreases significantly with large production volumes.

High Speed: Gravure presses can run at high speeds, ensuring efficient output for bulk orders.

Superior Print Quality

High Precision and Detail: Produces crisp, sharp, and highly detailed images and text, making it ideal for intricate designs and complex artwork.

Vibrant Colors: Achieves consistent and rich color density, even for large solid areas or gradients.

Photorealistic Output: Handles continuous tone images exceptionally well.

Longevity of Prints

Prints are highly resistant to fading, chemicals, and physical abrasion, ensuring the packaging looks great even after transportation and storage