Here are custom guidelines for plastic packaging bags, tailored to ensure smooth production, regulatory compliance, and strong branding:

1. Material Selection

Choose based on the product’s needs:

- PET/PE: For food-grade, lightweight, moisture-resistant packaging.

- NY/PE (Nylon/Polyethylene): For vacuum bags or puncture-resistant applications.

- PET/AL/PE or PET/MPET/PE: For high-barrier bags (e.g., coffee, snacks).

- CPP, BOPP, LLDPE: For various laminated or single-layer options.

- Other types material, If you do not know the exact packaging material, just let us know the products and storage request, then our sales will recommend the best material to you

2. Bag Structure & Style

3. Size & Thickness

Provide exact dimensions (width × height × gusset, if applicable).

Specify thickness in microns (e.g., 10–300 microns depending on product weight).

Indicate tolerance levels if exact sizing is critical.

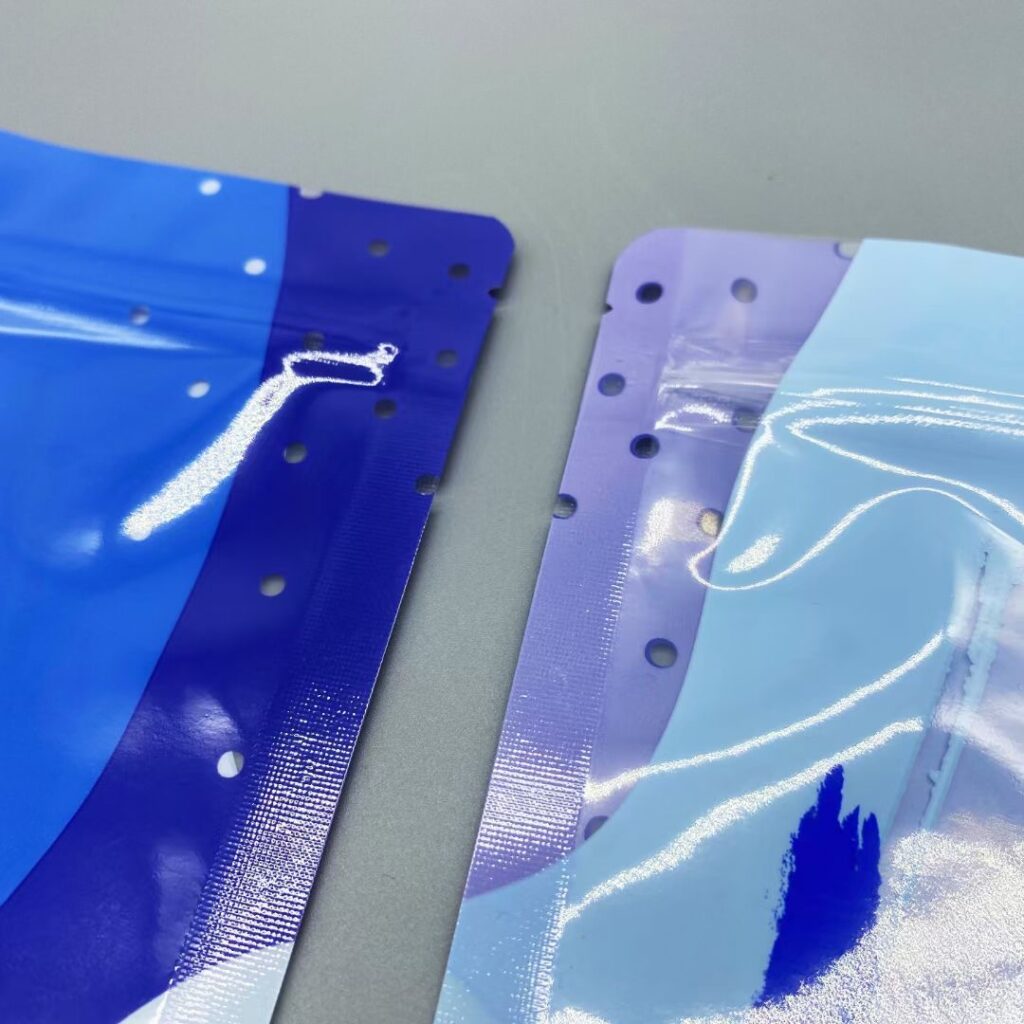

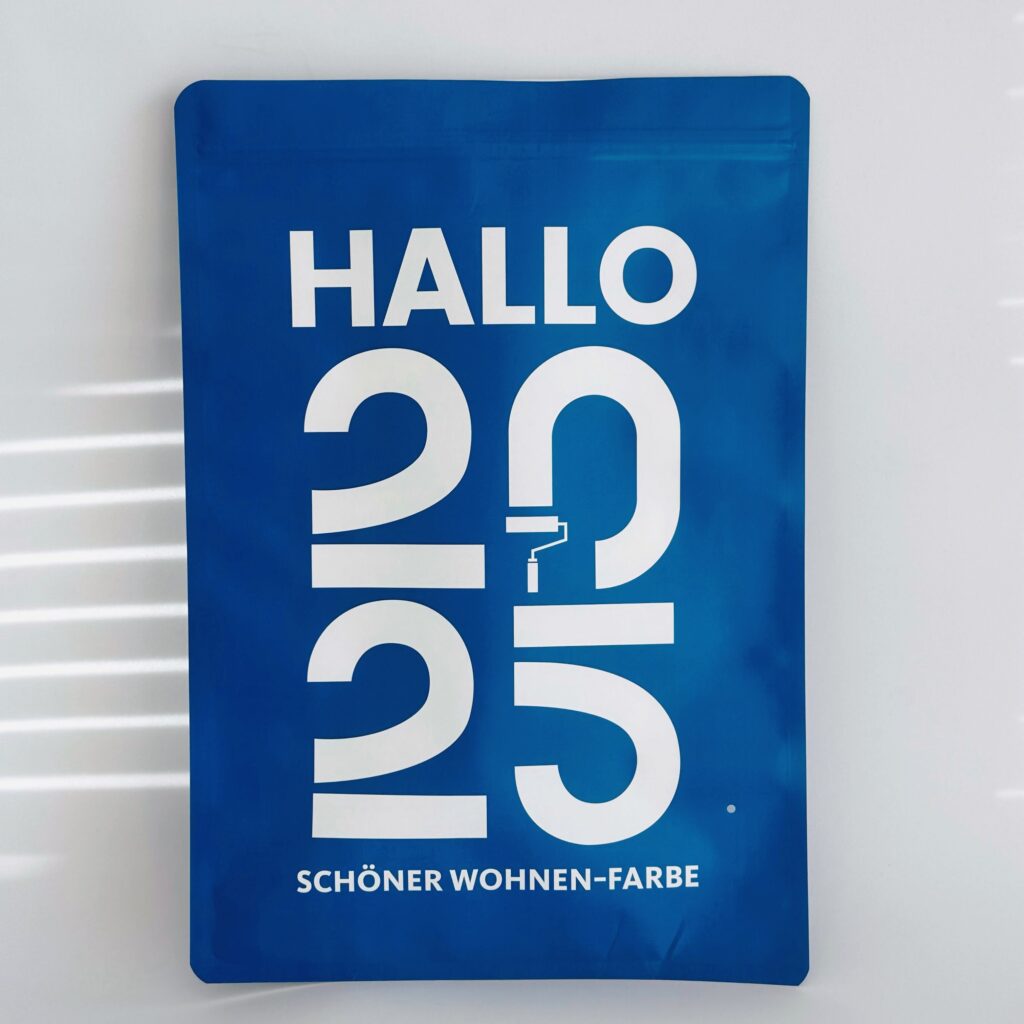

4. Printing Guidelines

Design format: Use AI, PDF, PSD, or CDR in CMYK mode.

Resolution: 300 DPI minimum.

Printing method: Gravure (for high-quality, high-volume) or digital (for smaller runs).

Max colors: Up to 11 colors.

Indicate areas for:

- Transparent windows

- Matte or gloss finishes

- Hot stamping / spot UV

5. Functional Add-ons (Optional)

Zipper / Velcro zipper / Child-resistant zipper

One-way degassing valve (for coffee)

Tear notch / hang hole / euro hole

Spout type & size (for liquid bags)

Handle cutout

Laser scoring (for easy tearing)

6. Compliance & Safety

Materials must be BPA-free, food-grade, and certified for relevant markets (e.g., FDA, EU 10/2011, LFGB).

If for retort or hot-fill, ensure heat resistance up to 135°C or as needed.

7. MOQ & Lead Time

Confirm minimum order quantity (often 10,000 pcs for custom prints with gravure printing). MOQ is 1

00pcs for digital printing.

Production time is usually 15–25 working days after design approval.

8. Storage & Shelf Life

Bags should be stored cool and dry, away from sunlight.

Recommend usage within 12–18 months after production to ensure print and seal integrity.